Tulip Clock

Home

Restoration and Repair

Clock Building

Contact Us

Press releases by Guild of Metalsmiths member, Pete Stanaitis

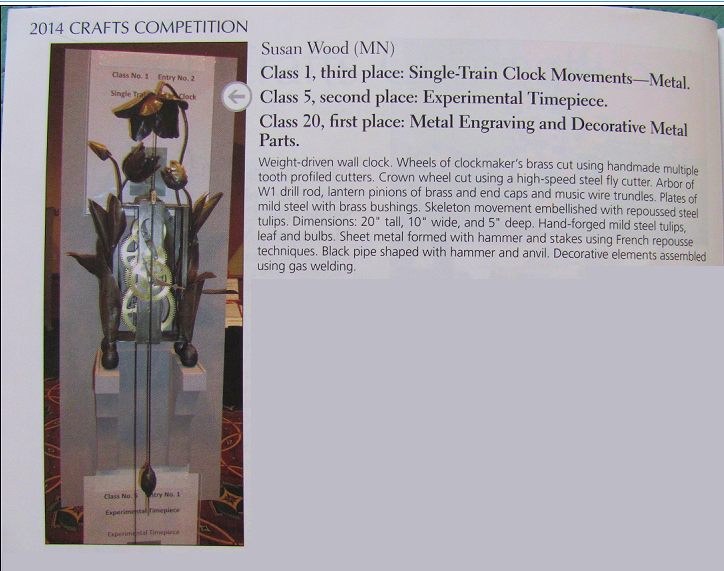

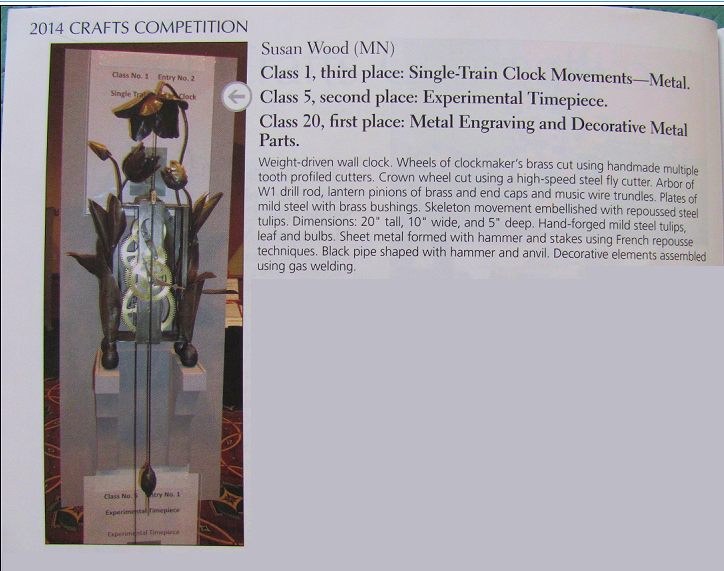

I see (below) that Susan has recently won 3 awards from the National Association of Watch and Clock Collectors!

Susan is also a member of the Guild of Metalsmiths, a Minnesota based blacksmithing organization.

We were lucky enough to be

able to see her Tulip Clock in operation at our annual conference last September.

So I was pleased to see this NAWCC

November/December 2014 article.

Susan has been a great resource to our club freely giving technical advice as well as being a willing worker in several areas.

'Way to go, Susan!

Now I see that the Spring, 2015 "Newsletter of the Horological Tool Chapter of the NAWCC" contains an in-depth article about

Susan's Tulip Clock:

PDF Version of Susan's Tulip Clock Article

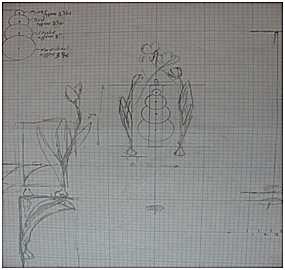

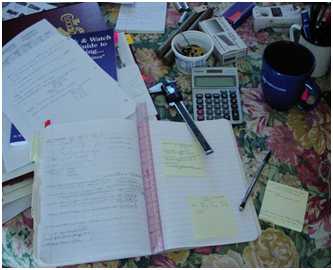

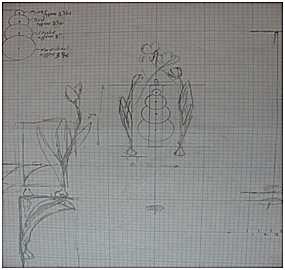

Inspiration and design begins November 2009

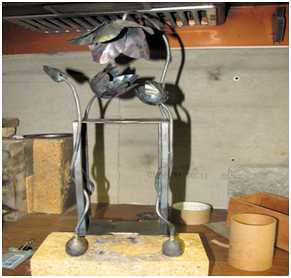

First experiments with the flowers

Forging bulbs

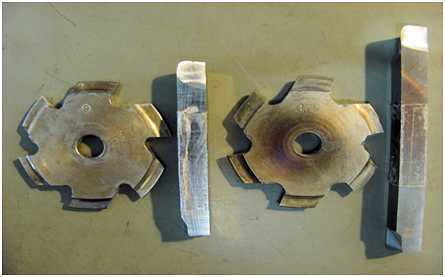

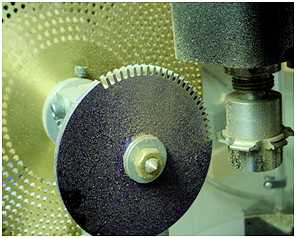

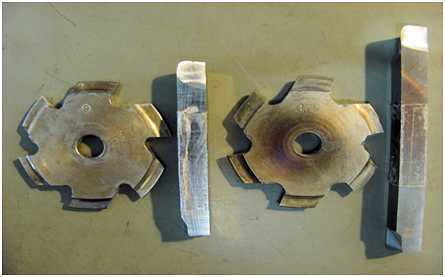

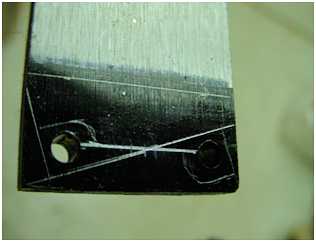

Two multiple tooth profiled wheel cutters and their form tools, module .9 and 1.0.

These were used to cut 1st, 2nd and 3rd wheels along with the hour wheel and its idler.

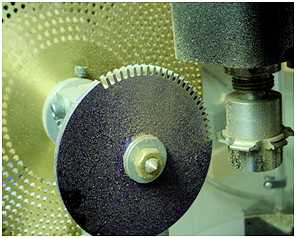

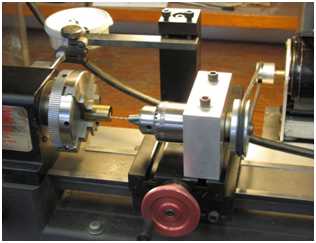

Cutting wheel teeth

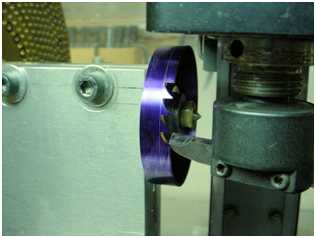

Crown wheel fabrication

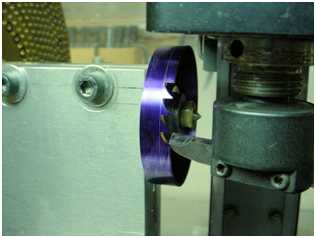

Cutting crown wheel with a fly cutter

Wheel Train complete

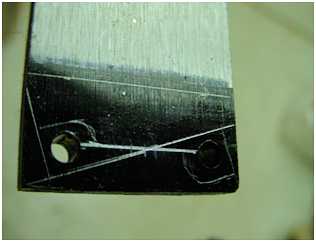

Layout of escape pallets

Forging and assembling clock frame

January 2010 components completed

-------------------

April 2014 work begins again

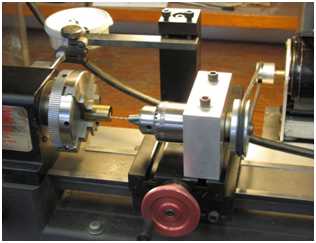

Arbors and lantern pinions fabricated

Wheels and pinions staked to arbors

Forging bridges

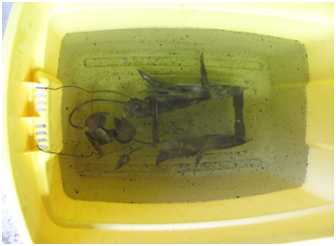

First assembly of wheel train between plates

Depthing of crown wheel and testing escape pallet bridges

First test run

Work on flowers gets refined

Overall design evolves

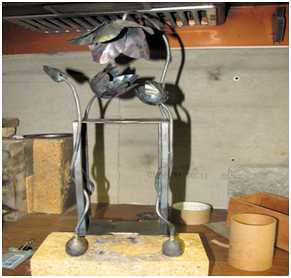

Welding flowers to frame

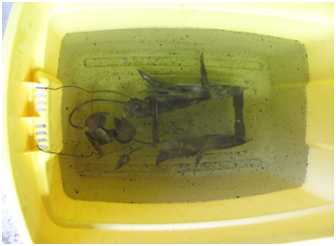

Pickeling before patina

Layout and cutting of hands

Clock complete June 2014

Clock Features

* Time only wheel train with hour and minute hands

* One week running with eight pound weight

* Crown wheel and verge escape with front mounted pendulum running at aproximately 5022 beats per hour

* Wheels of clockmakers brass cut using hand-made multiple tooth profiled cutters and sealed with a lacquer finish

* Crown wheel cut using a formed high speed steel fly cutter

* Arbors of W-1 drill rod, lantern pinions of brass end caps and music wire trundles

* Plates of mild steel with brass bushings

* Skeletin movement of forged mild steel

* Frame work embelished with mild steel tulip flowers that were formed with hammer and stakes using French repousse techniques

* Adjustable "bulb" feet made from black pipe formed with hammer and anvil

* Decorative elements attached using gas welding

* Patina created using heat, chemical treatments, and brass brushing then sealed with a lacquer finish

My Minneapolis, Minnesota phone number:

612-727-1300

Home

Restoration and Repair

Clock Building

Contact Us